| | I built this rustic style bar for my sisters wedding. Made from logs, corrugated iron and pallet wood. |

Start with 4 logs,

with as much character as you can find.

with as much character as you can find.

I used 90x45 mm pine.

That we had left, from

concrete form work.

That we had left, from

concrete form work.

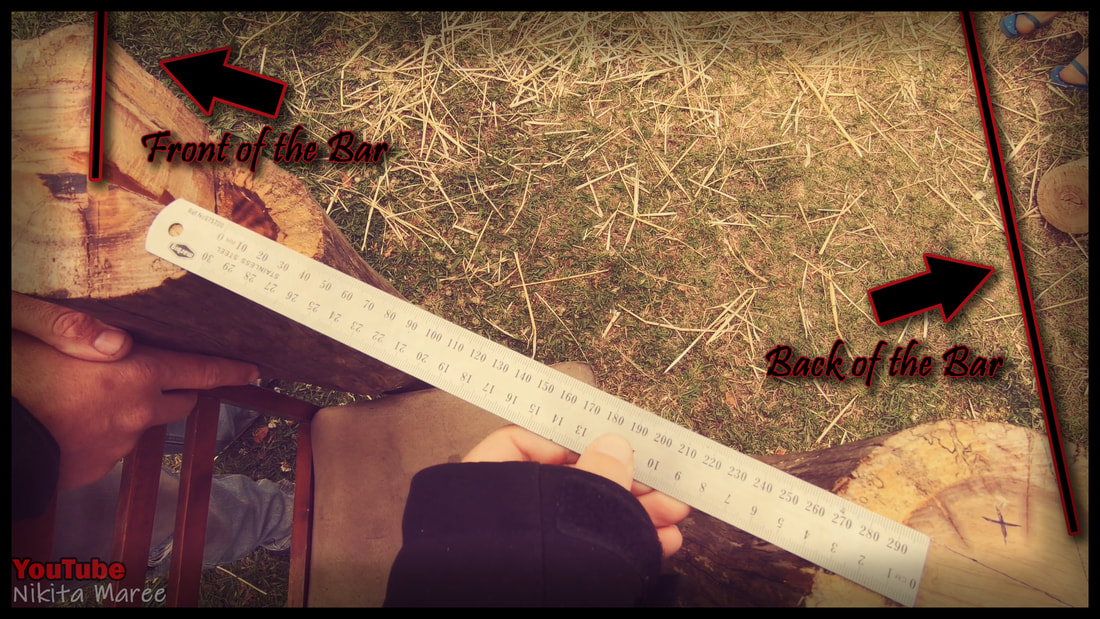

Measured the 4 posts

to the same length.

to the same length.

I cut the first post with the circular saw.

With the blade set at full depth.

With the blade set at full depth.

Rotating the log as I went.

If the blade depth is still not enough.

Just give the cut end a wack with a hammer.

Just give the cut end a wack with a hammer.

That took too long.

So I switched over to the chainsaw.

So I switched over to the chainsaw.

Now all 4 posts are the same length.

Here we are looking at the top

left hand side post.

Mark a straight line. Just shy of half way.

left hand side post.

Mark a straight line. Just shy of half way.

Then mark the center of that line.

Use a protractor to mark 60°

You should be left with something like this.

We are going to be cutting out

that 120° wedge.

that 120° wedge.

Draw a vertical line 100mm down,

from one side of the 120° wedge.

from one side of the 120° wedge.

Another vertical line for the other side.

Roughly sketch a horizontal line across,

joining those 2 points together.

joining those 2 points together.

Owen Is better on the chainsaw than I am.

So he volunteered to cut out the wedges for me.

So he volunteered to cut out the wedges for me.

The 120° wedge is now cut out.

The front right hand side

is a mirror image of the other side.

is a mirror image of the other side.

The back is marked out the same as

the front. Only we will be cutting out the

60° wedge opposed to the 120° wedge.

the front. Only we will be cutting out the

60° wedge opposed to the 120° wedge.

The ruler is demonstrating were

the side wall will be.

the side wall will be.

Now that all the top wedges are cut out.

We have to do the same for the

bottom of all the posts.

I am using a straight edge as a guide, to make

sure the bottom wedge lines up with the top.

We have to do the same for the

bottom of all the posts.

I am using a straight edge as a guide, to make

sure the bottom wedge lines up with the top.

Checking and adjusting the lines slightly.

To make sure the degrees are the same.

To make sure the degrees are the same.

I scraped as much concrete as I could

off of the pine lengths.

off of the pine lengths.

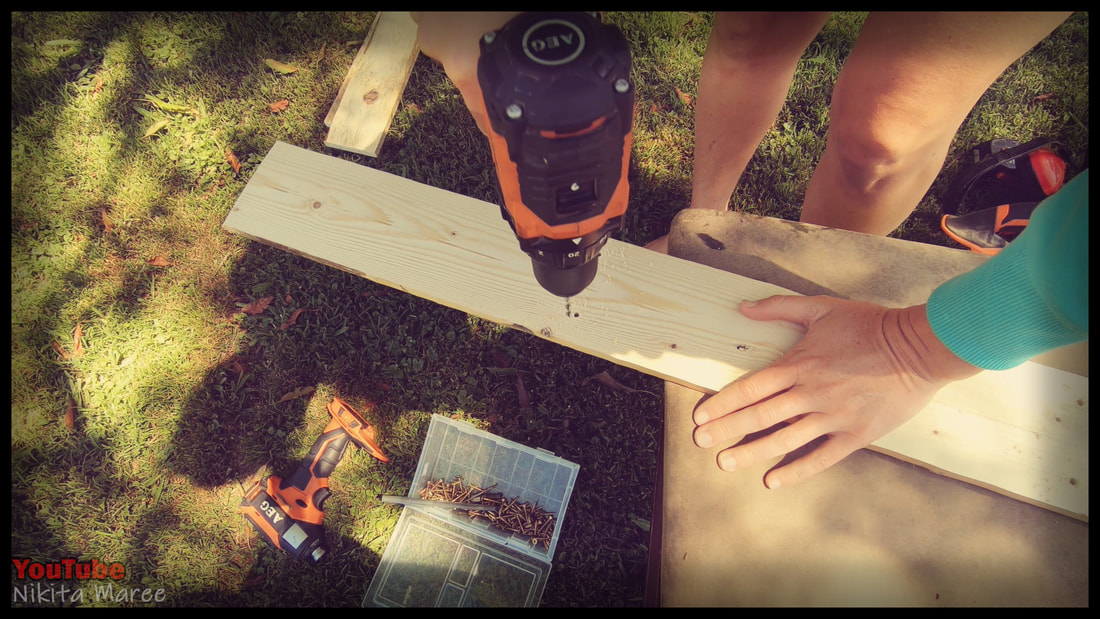

Mark the 2 spots to be drilled.

Pre-drill the holes.

Larger than the shank of the screws.

Larger than the shank of the screws.

Chamfer the holes.

I used a decking screw in reveres

to score the post bellow it.

to score the post bellow it.

Then with a drill bit smaller than the shank of the screw. Drill a pilot hole, to prevent any splitting.

Do the same for the bottom as we did

for the top.

Now we have the

front face of the bar all framed out.

for the top.

Now we have the

front face of the bar all framed out.

If you want the corrugated iron to fit neatly up against the post. . . .

You are going to need to cut a channel for

it to slide into.

it to slide into.

Only take a little off at a time.

Keep sliding the iron up against the post, to see were you need to take some more from.

Keep sliding the iron up against the post, to see were you need to take some more from.

Now the corrugated iron fits.

Square up one end of the iron.

With the cutting disk on an angle grinder.

With the cutting disk on an angle grinder.

Measure the height of the bar and

cut the iron to length.

cut the iron to length.

Use a nail and a hammer to punch a hole through the corrugated iron. So that the screws can easily got into the timber behind it.

Moving onto the sides of the bar.

Here I am marking 2 parallel lines.

So I can pre-cut a channel for the

corrugated iron.

corrugated iron.

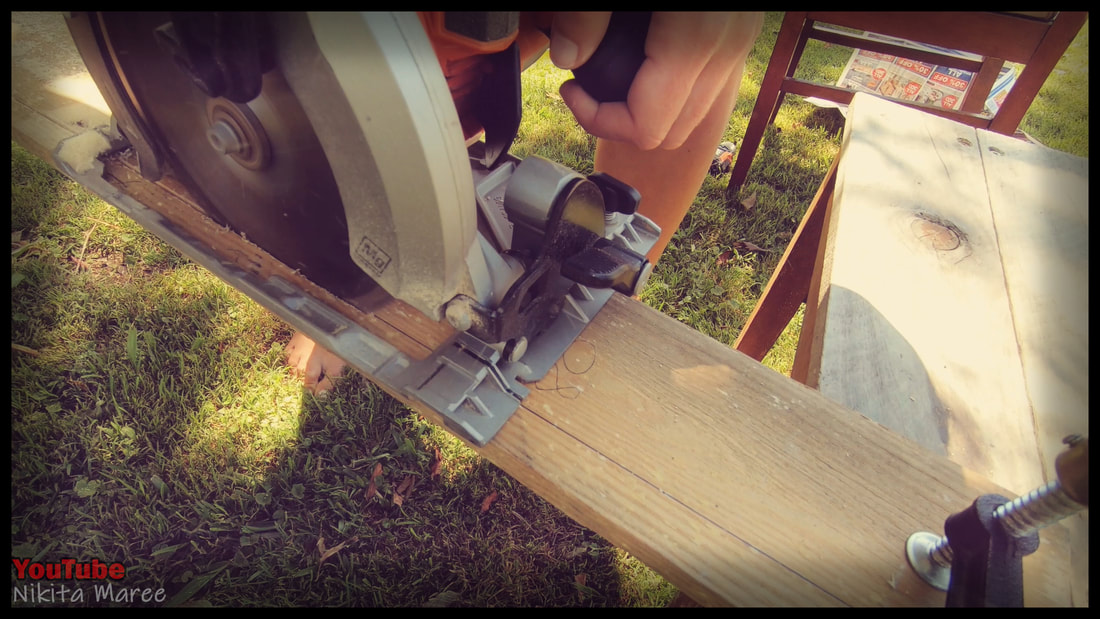

Set the circular saw to the ideal depth.

Cut along both the lines.

Pull out the scrap material.

Clean it up a little if need be.

The sides of the bar are half the width of a corrugated iron sheet.

Leaving the sides alone for now.

And moving onto framing up the back of the bar.

I cut the 2 lengths of pine to the same length.

And moving onto framing up the back of the bar.

I cut the 2 lengths of pine to the same length.

Roughly mark the angle.

Set the circular saw accordingly.

And make your cuts.

And make your cuts.

Moving on back to the sides.

We have the corrugated iron tucked into the groves

that we pre-cut earlier.

We have the corrugated iron tucked into the groves

that we pre-cut earlier.

It's easier to attach the iron first.

And then attach the frame afterwards.

These angles were cut at 35°

It's starting to come together.

Before we put the top on.

We awkwardly carry it into position.

We awkwardly carry it into position.

For the bar top. I cut and pulled apart

some pallets. And ran the palings

through the thicknesser.

some pallets. And ran the palings

through the thicknesser.

Square up the first paling.

Mark 20mm in, from both sides for

the screw holes.

the screw holes.

Pre-drill the hole.

Then chamfer.

Square it up again.

Attach your first paling.

Do the same thing for the paling

down the other end.

down the other end.

Fill in the center with as many loose palings

as required.

as required.

These will all be left oversized and we will just cut

them all at once to length, at the end.

them all at once to length, at the end.

If you are left with a gap that needs filling.

Chances are that one side of the gap is larger than the other.

Chances are that one side of the gap is larger than the other.

Take a measurement from either side.

Transfer those measurements to a paling and

draw a straight line between them.

draw a straight line between them.

Clamp one end to a bench.

Run the circular saw along your line.

Flip it over and re-clamp it.

Finish off the cut.

Now that it is cut to size . . .

Place that paling among the others.

Grab a straight edge and mark were the

screw holes will go.

screw holes will go.

Use some tape as a depth gauge on

your drill bit.

your drill bit.

So you can drill the holes right were

the palings are.

the palings are.

Chamfer all the holes.

Attach them all with cheap chipboard screws.

Now that it is all attached.

It is time to cut the top to size.

It is time to cut the top to size.

Measure 135mm from the screws.

Connect the dots, with a straight edge.

Clamp down a straight edge.

Run the circular saw along it.

I am glad we moved it before attaching the top.

Because I don't think we would of got

it out of the gate otherwise.

Also, it is heavy.

Because I don't think we would of got

it out of the gate otherwise.

Also, it is heavy.

I ran some paling through the table saw,

set at 30mm.

set at 30mm.

Pre-drilled and chamfered the holes.

These will be attached to the entire

underside of the bar.

underside of the bar.

Because of the amount of over hang there is

at the front of the bar, I didn't won't any

twisting and warping in the individual pieces.

at the front of the bar, I didn't won't any

twisting and warping in the individual pieces.

If you like working with pallets,

or other cheaper materials.

You might want to check out

some of my videos.

or other cheaper materials.

You might want to check out

some of my videos.

RSS Feed

RSS Feed